Published in HARTENERGY E&P magazine, John Flavell Smith, Wireless Seismic, Inc.

The low oil price has forced our industry to take a comprehensive top-to-bottom look at the cost of doing business. The current commodity pricing levels have shown little sign of changing, so companies have had to quickly adjust to the “new normal.” However, “It’s an ill wind that blows nobody any good,” as exploration and production companies take advantage of significantly lower seismic data acquisition prices when compared to recent years.

Further down the food chain, the same situation applies with equipment suppliers sharpening their pencils to offer contractors the most competitive deals in a tight market. An obvious and effective short-term way to ease cash outflows is to slash capital spending. From a seismic contractor’s perspective, the most logical steps might be to make do with the recording equipment already in their inventories or to buy the cheapest equipment available. However, this approach might look like a good short-term decision, but to focus on the balance sheet at the expense of the profit and loss account could have the medium-term effect of further reducing already thin margins.

It is important that contractors look beyond the purchase price of the system and consider the true cost of ownership. In many cases, the purchase price of a new system could be fully recouped in just a few months through greatly improved operational efficiencies.

In the current industry downturn, seismic contractors have tens, if not hundreds of thousands of cable channels stacked in their warehouses. Again, with an eye to the balance sheet, when the markets start to recover, contractors will understandably wish to bring these aging systems out of retirement. There is the strong possibility that these systems have deteriorated in storage and will present a multitude of problems when deployed in the field, severely impacting the crew productivity and profitability. Hence, there is a strong argument for contractors to upgrade their systems as the market recovers to avoid this potential pitfall.

CABLE VS. CABLELESS

Consider the purchase of a land seismic recording system. In the interests of industry harmony, let’s start by stating that there are no bad systems on the market and each system has it pros and cons, which may make them more suitable to a particular type of acquisition or terrain.

Cable systems can be bought relatively cheaply (the word “relatively” is used advisedly). The systems work well in most situations, but the cables themselves are prone to leakage, especially in wet environments, resulting in considerable time spent at the beginning of each shooting day troubleshooting the cable network. This shortened workday directly reduces crew productivity.

The cables are heavy and bulky, which add to the cost and complexity of logistics and crew headcount. In populated or agricultural areas, wherethere may be local opposition to exploration, the cables are vulnerable to damage, which further impacts productivity and the operational expenses and costs of cable repairs (Image 1).

Autonomous nodal systems escape the problems of cables, giving optimal productivity, as the contractor can just acquire data almost regardless ofenvironmental conditions. These lower weight and volume systems ease logistics and transportation costs. However, some of these gains are reversed by the need to harvest the data, either in situ or at the base camp–both instances requiring complex transcription and trained staff, and that is without the 10%-15% extra channels to replace those taken off-line for harvesting and re-charging.

As these nodal systems lack “command and control” capabilities, the operator does not know the status of the system, and expensive mistakes can be made, leading to the negative outcomes previously cited–sometimes shooting data that has to be re-acquired. Data are stored for long periods in the field units, making the valuable dataset vulnerable to theft.

REAL-TIME AND CABLE-FREE

Wireless Seismic, Inc.’s cable-free RT System 2 has a scalable real-time radio network giving the observer complete control at all times. RT System 2 is capable of recording many thousands of channels in real time, just like a traditional cable system. As it is cable free, logistics are eased, and as it is a real-time system, there is no complex data harvesting and associated infrastructure or “last patch” effect.

The freedom from cables also gives flexibility in deployment. Imagine a contractor using a blind nodal system to acquire a 3D survey with 10,000active channels deployed in the field. During the survey, the contractor will harvest the data from the nodes on a routine rolling basis, perhaps taking 10%-15% of the nodes offline at any one time to download the data and often to recharge the batteries before they are re-deployed on the line. At the end of the survey, all of the nodes have to be collected fromthe field and moved to the base camp to download the massive amount of data. Inevitably, this process takes time, and the client frequently has to wait for more than a month before having access to the complete dataset.

RT System 2 transfers data in real time, so it does not require a harvesting function, and it avoids both the “last patch” delay in data availability and the requirement for extra capital expenditure on more nodes to compensate for the absence of nodes from the line during data harvesting.

During a recent 3D survey over varied terrain in the Kurdish Autonomous region of Iraq, a number of advantages of a real-time and cable-free system were demonstrated. RT System 2 was deployed in an agricultural area when the fields were being plowed in preparation for sowing. The seismic contractor worked with the farmers to ensure minimal disruption to the crew operations. Because the RT System 2 Wireless Remote Units (WRUs) are free-standing, the farmers were able to plow around the WRUs with minimal inconvenience to their plowing schedule (Image 2). Had the contractor been using a cabled system, the disruption to both the contractor and the farmers would have been significant in terms of both lost time and damaged equipment.

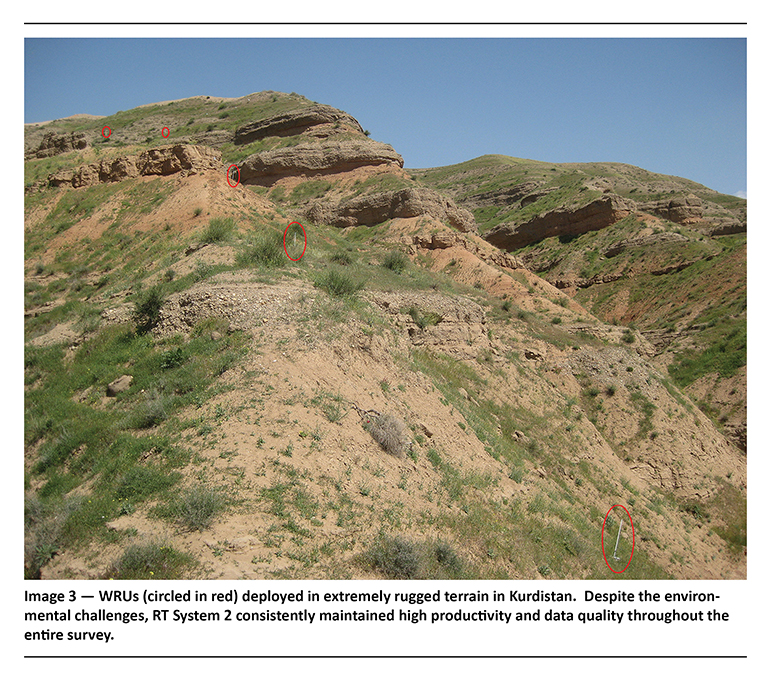

Areas of the prospect were steep and rocky, which proved to be a difficult medium in which to consistently plant geophones (Image 3). The live spread comprised up to 11,000 channels with each string having 2 X 6 geophones, which meant that 132,000 individual geophones were required to be planted. With the RT System 2 real-time QC, poor geophone plants were detected instantly across the entire spread. Poorly planted geophones were identified and re-planted properly, thus improving data quality. Statistics can also be kept on planting quality for each layout crew.

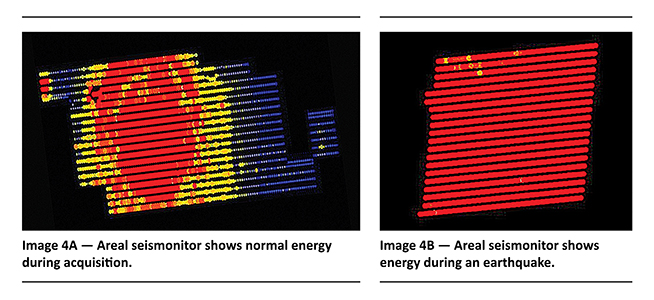

An earthquake measuring 6.8 on the Richter scale occurred overnight close to the prospect during the survey, with its epicenter over the border in Iran. Aftershocks persisted for 90 seconds every 5 minutes or so over several days and obliterated the data. There was no physical evidence of the aftershocks at the recorder, but it could be seen clearly on the RT System 2 data displays. Consequently, the crew was able to cease operations as the aftershocks occurred, avoiding acquiring data that otherwise would have been swamped by noise (Image 4).

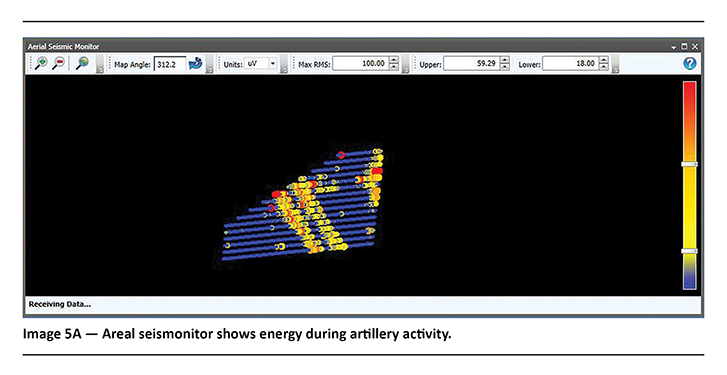

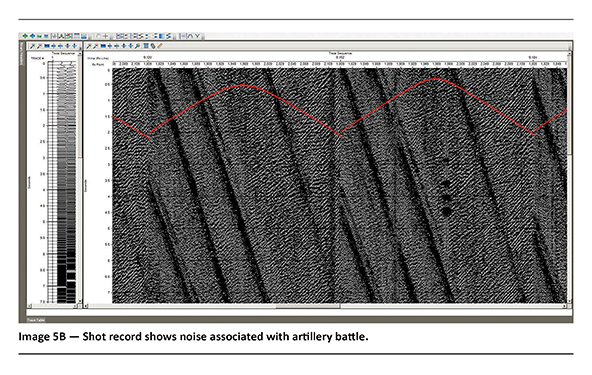

At times, there was artillery fire from ISIS and/or Peshmerga forces at a distance of 25-30 km from the survey area. As with the earthquake aftershocks, the bombardments could not be heard or physically sensed at the recorder or on the line, but could be seen distinctly on RT System 2 data displays. Real-time QC enabled the noise to be monitored and the acquisition suspended and restarted as required (Image 5).

The lower weight and volume of cable-free systems reduces transportation costs and effort. Contractors using RT System 2 consistently enjoy reduced headcount on the crew, with consequent reductions in camp size, the number of vehicles on the crew, and the number of vehicle movements, all of which leads to a significant decrease in the headline HSE exposure of the crew. Since the equipment can be re-deployed more efficiently because of its high mobility, fewer channels are required on the crew, resulting in a reduction of capital costs.

In conclusion, the constant QC gives the observer the tools to know when to start and stop acquisition to optimize data quality and avoid the pitfalls of nodal systems. RT System 2 crews have lower headcounts that reduce carbon and environmental footprints. Most important of all, operational expenses are minimized, which is just what the industry needs in this “new normal” pricing climate.